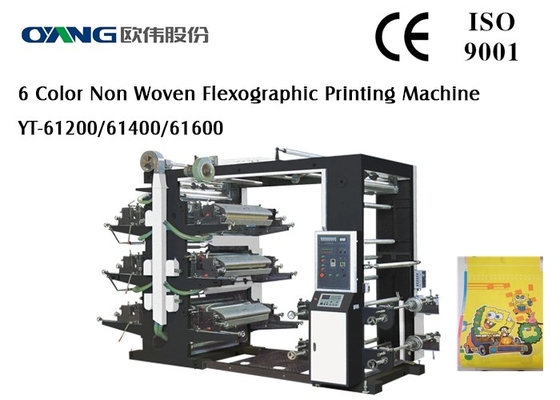

6 Color Flexographic Printing Machinery For Non Woven Fabric / Pe Film Printing

Description:

6 Color Flexographic Printing Machinery For Non Woven Fabric / Pe Film Printing

1. Easy operation, flexible starting, accurate color register.

2. The meter counter can set printing quantity according to the requirements. Stop the machine automatically at the quantity or when the material is cut off.

3. Pneumatic printing cylinder lift and lower, it will stir the printing ink automatically after lifting.

4. The printing ink is spread by the anilox cylinder with even ink color.

5. Reliable drying system coordinated with high speed rotation, it will automatically break circuit when the machine stops.

6.360° continuous and adjustable longitudinal register device.

7. The frequency control of motor speed adapts to different printing speeds.

8. There are Jogging/Stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed.

Specifications:

|

Type |

YT-6600 |

YT-6800 |

YT-61000 |

|

Max.Effective Printing Width |

560mm |

760mm |

960mm |

|

Max.Web Width |

600mm |

800mm |

1000mm |

|

Max.Printing Speed |

50m/min |

50m/min |

50m/min |

|

Max.Mechanical Speed |

60 m/min |

60 m/min |

60 m/min |

|

Max.Diameter of Roll Material |

450mm |

450mm |

450mm |

|

Internal Diameter of Roll Core |

76mm |

76mm |

76mm |

|

Rang of Repeat Printing Length |

191-914mm |

191-914mm |

191-914mm |

|

Accuracy of Registration |

±0.5mm |

±0.5mm |

±0.5mm |

|

Plate Thickness |

2.38mm |

2.38mm |

2.38mm |

|

Heating Power |

7Kw |

10.5Kw |

14Kw |

|

Total Power |

11.5Kw |

15Kw |

18.5Kw |

|

Weight of Machine |

3000kg |

3500kg |

4000kg |

|

Overall Dimension |

L4200×W1600×H2400mm |

L4300×W1900×H2500mm |

L4300×W2100×H2500mm |

Applications:

This machine can printing non woven fabirc ,roll paper,plastic film.

LDPE: 28 ~ 100μm LLDPE: 30 ~ 100μm HDPE: 25 ~ 100μm CPP: 20 ~ 60μm PP: 23 ~ 65μm NY: 20 ~ 50μm PETP: 16 ~ 60μm OPP: 18 ~ 70μm BOPP: 17 ~ 60μm OPA: 20 ~ 60μm Plating film: 30 ~ 80μm Aluminum: 25 ~ 200μm Cellophane: 30 ~ 100g/m2 Paper : 30 ~ 350g/m2 Wrapping paper : 30 ~ 100g/ m2

Competitive Advantage:

1. Low speed and full load startup; stable running by tension control when increasing and decreasing speed;

noise is decreased

2. Aluminum roller adopts the Japan semi-sealing small bearing; flinty oxidation, static and dynamic balancing

treatments are conducted; low resistance and small flop.

3. The special made modulus angular gears adopted; accurate printing size and full printing specifications

( 6.35mm is a spec)

4. With single doctor blade and circulating pump

5. The grouped and controlled bottom roller processed with Germany particular steel materials processed with

special techniques and electrically gilded with 0.1mm hard chromium protective layers

6. With hard chroming anilox roll

7. The machine use hydraulic printing-roll loading system which can automatically load printing rolls and run

inks after the machine alarm working signal.

8. Good quality printing

9. Brilliance color appearance.

10. The operation is easier and more convenient,the register is more accurate,and the lifespan is also longer

Printing Samples:

![]()