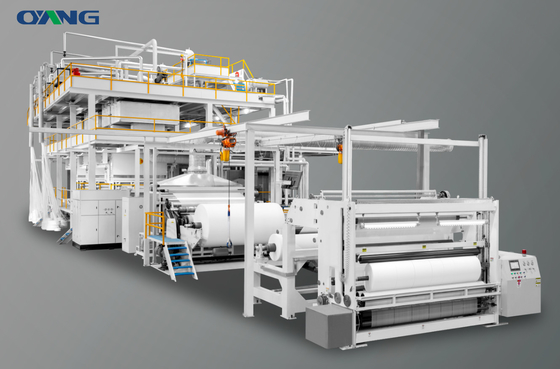

3200mm SMS PP Non Woven Fabric Production Line High Speed 0 - 350m/min

Parts Of PP Non Woven Fabric production Line:

Recycle extruder---->Main extruder---->Filter---->Metering pump---->Monomer suction device--->Spinning box---->Quenching air chamber---->Stretching device---->Web former---->Calender---->Winder---->Slitter

Spun-Laid Process And Technical Flow Chart:

Additive(Recycling offcut fabric)---->Raw material---->Melting---->Filtering---->Measuring ---->Spinning---->Cooling---->Stretching---->Web forming---->Calendering---->Winding----> Cutting---->Final product

Specifications

| Model No. | ONL-1600SMS | ONL-2400SMS | ONL-3200SmS |

| Working Width | 1600mm | 2400mm | 3200mm |

| Fabric GSM | 15~250 | 15~250 | 10~250 |

| Power Input | 600KVA | 800KVA | 1000KVA |

| Consumption | 400KW | 600KW | 800KW |

| Annual Output | 3500T | 5000T | 6500T |

| Embossing Pattern | Diamond, Oval | ||

| Fineness | 1.5~2.5dtex | ||

Features

According to the advanced technology from abroad and our actual operating experience, we lanched the professional nonwoven fabric making equipment with our new research result. Small investment, less space occupied, simply production process, easy operating, labor saving, ect. Are the advantages of our machine.

Using polypropylene (PP) as raw material, under several processing, to get non-woven fabric material finally. Our material get even surface, high strength, air permeability, and perfect touch feeling, etc. Which are widely used in protective equipment, health care, house use, fashion shopping bags, industrial product, construction, etc. We can customize 1.6-3.2 m width's machine according to customer requirements.

Application:

Surgical gown&cap, patient clothes, bed sheet, pillow covers, glover, diaper, Shoe cover, curtains, etc.

Baby diaper, feminine hygiene, hygiene pad, baby training trouser, incontinence pads. etc. Cover of the high absorbent material after hydrophilic treatment, diaper edge for preventing Leaking. Diaper backing after composite with other material etc

Shopping bag, tarpauins, tents, bag for rice/sugar, luggage, vacuum cleaner bag, buff pad, Interlining and cloth, shoulder padding etc.

Cover tree, cope cover, garden cover etc.