B330 Model Semi Auto 200pcs/Min 330mm Bag Width Suqare Bottom Paper Bag Machine SOS Bag

Product introduction:

Fully automatic square bottom paper bag machine is designed for the production of paper bags with twisted handles. It is suitable for mass production of shopping bags in industries such as food and clothing.

square bottom paper bag making machine forming the paper bag in one process from printed or unprinted roll paper ,side gluing, roll folding, roll paper cutting, bottom folding, bottom gluing, bottom forming, bag formation at a stroke. This machine controls by PC programmable servo motor through the human-machine touch screen interface. It can produce various of specifications paper bags.

This machine have advantages of high speed, quickly replace the paper bag specifications, more wide range adjusting etc. It is an ideal machine for producing food bag, shopping handles bag.

Main machine parameters:

| Model | New world -B220 | New world -B330 | New world -B400 | New world -B460 |

| Paper bag length | 191-430mm | 280-510mm | 280-600mm | 320-780mm |

| Paper bag width | 80-200mm | 150-330mm | 150-400mm | 220-460mm |

| Paper bag bottom width | 50-120mm | 70-150mm | 90-200mm | 80-260mm |

| Paper thickness | 50-140g/m2 | 60-140g/m2 | 70-140g/m2 | 80-150g/m2 |

| Machine Speed | 80-250pcs/min | 80-200pcs/min | 80-200pcs/min | 80-150pcs/min |

| Paper bag speed | 100-180 pcs/min | 100-160 pcs/min | 100-160 pcs/min | 100-150 pcs/min |

| Paper roll width | 290-630mm | 470-990mm | 510-1230mm | 670-1470mm |

| Roll paper diameter | 1500mm | 1500mm | 1500mm | 1500mm |

| Machine weight | 5600kg | 8000kg | 9000kg | 11000kg |

| Machine size | 8600×2600×1900 mm | 9500×2600×1900 mm | 10700×2600×1900 mm | 10700×2600×2000 mm |

Performance characteristics:

1. Use MITSUBISHI JAPAN Touch Screen Human-Computer Interface, operate and control easily.

2. Adopt MITSUBISHI JAPAN Motion Control, integrated with optical fiber, ensure high speed running steadily.

3. MITSUBISHI JAPAN Servo Motor and Germany Original SICK Photoelectric Eye Correction, tracking printing bag accurately.

4. Raw material load adopt Hydraulic pressure cylinder up and down structure, unwinding adopt auto tension control.

5. Raw material unwinding EPC adopt TECHMACH (CHINA), Reduce adjustment time.

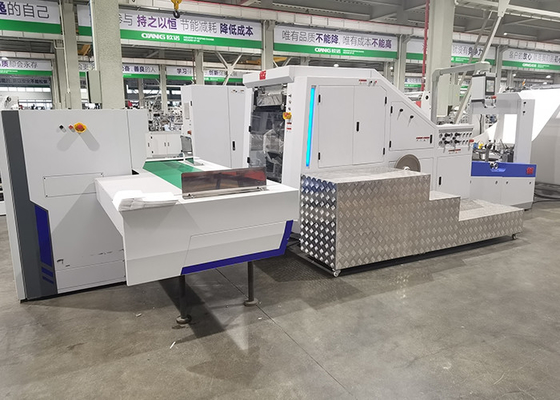

Product display:

![]()

![]()

![]()

ABOUT US:

Wenzhou Ounuo Machinery Co., Ltd. is a professional manufacturer of non woven bag making machines, nonwoven printing machines, soft handle sealing machines and relevant equipment. We keep innovating and learning the latest technology, to provide you with quality products.

Our company has an area of 8,000 square meters and 130 on-the-job employees. We have four production lines in total. They are divided into non-woven bag making machine lines, soft handle sealing machine lines, flexo printing machine lines and paper cup machine lines. We can ensure our delivery time within 15 working days.

Our strong and professional sales team will provide you with details of machine introduction. According to each customer's different requests, we provide individual and special machine solutions.

In the future of environmentally friendly packaging industry,

We have excellent competitive products innovative environmentally friendly production solutions.

And based on close partnerships,

Create value and unlimited possibilities above the needs of our customers.

![]()

AFTER-SALE SERVICE

Installation:

The seller will send 1 engineer to install, test the production line and train customers’ workers in buyers’ factory. It will take 1 week to 10 days for whole installation and training.

The buyer should cover engineers’ salary, visa cost, Round air tickets, accommodations, transportation in buyers’ country, food, medical care, safety cost, and related cost happens in buyers’ country. Also, the buyer should prepare enough labor, electric wire outside the control panel, Air Compressor and tools for installations.

Engineer’s Salary:

USD 100/day, depending on how the engineer makes you satisfied. The date he arrives and leaves shall be counted as paid day.

Warranty:

Warranty period for the delivered equipment will be 12 months after completion of erection but not later than 18 months after shipment. In case any item proves to be defective and the damage is confirmed by seller’s technicians within this period, the seller will at their choice either send engineer to repair or supply a new one for replacement free of charge on the basis of CNF delivery.

The above item does not include the parts, which have regular spares or the parts damaged from normal wear, abnormal operation, improper maintenance and inadequate civil works. The seller is not liable for any production loss under any circumstances.

Packing:

As per export standard, they will also be treated before delivery against damage and rusting